RAW CANE HARVEST

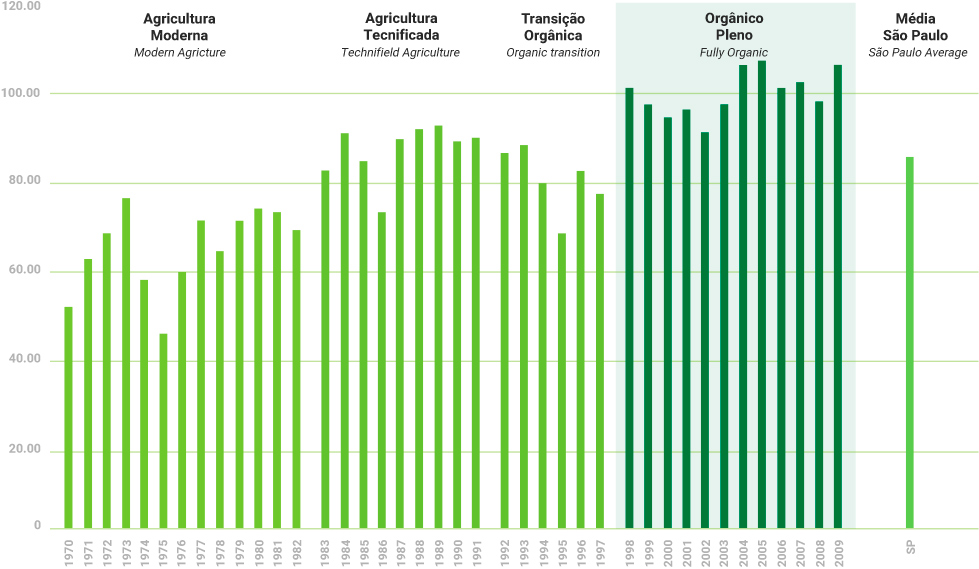

The new production system, developed by the Balbo Group, enables cane harvesting without burning. The harvesters while removing the cane, promote the replacement of green straw in the soil, which in turn creates a mulch that protects the soil from erosion and insolation.

In our system, the land also wins. It receives organic, liquid and solid effluents, which are by-products of the industry, called vinasse and filter cake. As the production cycle of a cane field is approximately 6 years, following 5 harvests, the soil is revolved every 6 or 7 years. In addition, machines and vehicles have high floatation tracks and tires, minimizing soil compaction.

These techniques help to maintain soil fertility and its active bio-structure, creating a favorable environment for the action of beneficial microorganisms and for the infiltration of water and air, which are essential for the development of plants, ensuring balanced and harmonious coexistence between farmers and nature.